Hesitation or bog on acceleration

The BBD is a two-barrel downdraft carb which incorporates three basic fuel metering systems.

In addition to these systems, the carburetor uses an automatic choke and choke diaphragm.

Chrysler Corp models are equipped with an electric assisted choke which provides for shorter choke "on" time during warm weather. The choke diaphragm prevents over choking by opening the choke valve when the engine is being cranked.

On Chrysler Corp models equipped with an EGR system, there is an additional vacuum port in the carburetor. If Ported Vacuum Control System (PVCS) is used, the vacuum port is located in the base of the carburetor. If Venturi Vacuum Control System (VVCS) is used, vacuum port is found in the side of the carburetor about the throttle valve. This is most typical in California models.

Carter manufactured two main styles over the years.

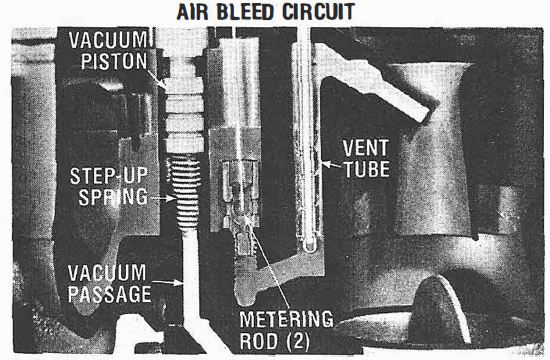

AIR BLEED

The air bleed circuit used prior to 197 4 has an emulsion tube or vent tube that extends downward into the high speed well. This tube mixes air with the fuel before it leaves the high speed well. The air bled design always uses “down hill” nozzles. The air bleed in the high speed circuit also serve as-an anti-percolator passage.

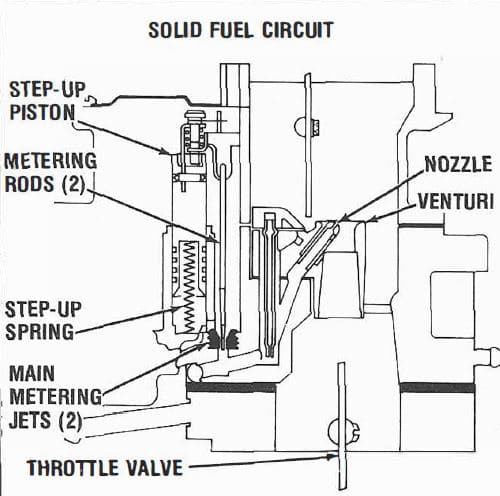

SOLID FUEL

The solid fuel design, 1974 and ‘later, takes solid fuel from the high speed well and bleeds air into the circuit at the top through the extended vent tubes located in the cluster, closer to the tip of the nozzle. The solid fuel design always uses “uphill” nozzles and gives a closer calibration to meet the emission standards and also serves as an anti-percolator passage.